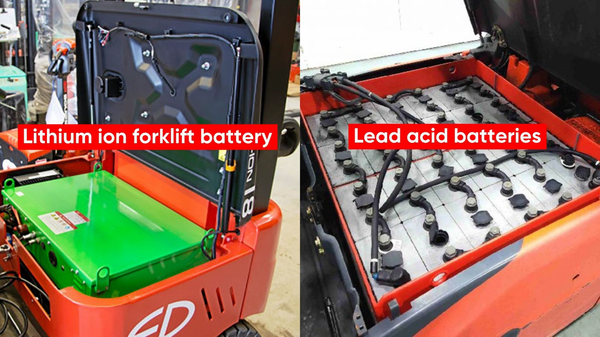

In the evolving landscape of UK warehousing and logistics, the choice of forklift battery technology is a critical decision impacting operational efficiency, long-term costs, and sustainability. Beyond the initial purchase price, the Total Cost of Ownership (TCO) provides a comprehensive financial assessment, accounting for all expenses over an asset's lifespan. This article meticulously compares lead-acid batteries, the industry's traditional workhorses, with modern, increasingly popular lithium-ion counterparts, dissecting each TCO component. While lead-acid batteries currently dominate the UK market, lithium-ion technology is rapidly gaining traction, projected to account for 50% of battery types by 2027, underscoring its growing recognition for long-term advantages.

Initial Investment: The Upfront Cost Story

The initial purchase price is often the most visible financial consideration for businesses.

Lead-Acid Forklifts: The Traditional Entry Point Lead-acid batteries have historically been favoured for their lower initial acquisition cost, positioning them as a financially accessible option for businesses with immediate budget constraints. Typical new lead-acid forklift battery prices in the UK generally range from £1,000 to £3,000. A 48V – 37kWh lead-acid traction battery, a popular size, is listed around £5,682. Individual 2V cells, which constitute a battery pack, can range from £96.99 to £305.99. Beyond providing power, lead-acid batteries inherently serve as a crucial counterbalance in forklifts, preventing tipping when lifting heavy loads. For those seeking to further reduce initial outlay, refurbished lead-acid batteries are available, starting from approximately £800, though these may not offer the same longevity or performance as new units.

Lithium-Ion Forklifts: The Higher Initial Outlay Lithium-ion batteries typically command a higher upfront price compared to lead-acid alternatives, often the primary hurdle for businesses considering the switch. New lithium-ion forklift battery costs in the UK generally fall within the £5,000 to £10,000 range. Some high-end or larger capacity units can range from $6,000 to $25,000, with specific examples like an 80V 775Ah unit priced at £11,827. Smaller capacity lithium batteries (e.g., 48V 10Ah) are listed at significantly lower prices, around £288-£324, likely for lighter-duty pallet trucks rather than full-sized forklifts.

The higher upfront cost of lithium-ion batteries positions them not as a mere expense, but as a strategic investment. The growing market share of Li-ion indicates that UK businesses are increasingly adopting this investment mindset, looking beyond immediate costs to long-term value. An additional initial cost when transitioning from lead-acid to lithium-ion is the requirement for a compatible charger, which can add £500 or more. Furthermore, professional installation for any new battery can also add £100-£300. For an accurate TCO calculation, businesses must budget for these ancillary costs.

|

Battery Type |

Typical Voltage |

Estimated Battery Cost (New, UK £) |

Notes |

|

Lead-Acid |

24V, 48V, 80V |

£1,000 - £5,682 |

Lower entry point; acts as counterbalance; refurbished options from £800. |

|

Lithium-Ion |

24V, 48V, 80V |

£5,000 - £25,000 |

Higher initial outlay; requires compatible charger (£500+); professional installation (£100-£300). |

Energy Consumption & Charging Efficiency: Fueling Your Operations

The efficiency with which a battery converts and stores electrical energy, alongside its charging characteristics, directly impacts a business's electricity bills and operational throughput.

Lead-Acid: Energy Conversion and Charging Cycles Lead-acid batteries typically convert stored charge at an efficiency of around 70-80%. This means a significant portion (20-30%) of the electricity drawn during charging is dissipated as heat, representing wasted energy and consequently higher electricity bills. These batteries demand lengthy charging times, usually requiring 8 to 12 hours for a full charge. Critically, after a full charge, lead-acid batteries necessitate an additional 6 to 8 hours for a cooling-off period before they can be safely returned to service. This extends the total downtime per charge cycle to a substantial 16 hours. "Opportunity charging" – short, frequent top-ups during breaks – is generally detrimental to lead-acid batteries. A key operational drawback is that lead-acid battery performance, including voltage and lifting capacity, noticeably declines as the charge depletes.

Lithium-Ion: Maximising Every Watt and Faster Turnaround Lithium-ion batteries boast impressive energy efficiency, often reaching 95% or even 98-99%. This superior conversion rate directly translates to lower electricity consumption and significantly reduced energy bills over time. Charging times are dramatically shorter, typically ranging from 1 to 3 hours for a full charge. Unlike lead-acid, lithium-ion batteries thrive on "opportunity charging." They can be safely recharged during short breaks (15-30 minutes) or idle periods without any negative impact on their lifespan or performance. This fundamental difference is not merely about faster charging; it is about unlocking profound operational flexibility and continuous uptime. A single lithium-ion battery can often power a forklift through multiple shifts or even 24/7 operations, effectively eliminating the need for spare batteries, the labour associated with battery changeovers, and dedicated charging infrastructure. A significant advantage is the absence of a required cooling-off period after charging, allowing forklifts to return to service immediately. Lithium-ion batteries deliver consistent power output throughout their entire discharge cycle.

|

Feature |

Lead-Acid |

Lithium-Ion |

|

Energy Efficiency (%) |

70-80% |

95-99% |

|

Full Charge Time (hours) |

8-12 hours |

1-3 hours |

|

Cooling Time Required |

Yes (6-8 hours) |

No |

|

Opportunity Charging Capability |

No (detrimental) |

Yes (beneficial) |

|

Power Output Consistency |

Declining with discharge |

Consistent throughout discharge |

Maintenance Requirements: Uncovering the Hidden Costs of Upkeep

The ongoing maintenance demands of forklift batteries represent a significant, often underestimated component of the Total Cost of Ownership.

Lead-Acid: A Demanding and Costly Regimen Lead-acid batteries are known for their demanding and diligent maintenance requirements. Regular refilling with distilled or deionised water is crucial, typically weekly in summer and biweekly in winter, or every 5-10 charge cycles. The cost of deionised water for industrial use can be around £12-£15 for a 25-litre container. Monthly equalisation charges are necessary to reverse sulfation build-up and balance the power outputs of individual battery cells, often taking 3 hours longer than a normal charge. Regular cleaning of battery terminals and routine inspections are essential. Lead-acid batteries operate optimally within a narrow temperature range of 20-25°C and generate significant heat during charging, necessitating temperature-controlled charging spaces. In cold environments, they lose substantial capacity (30-40% at 0°C), potentially requiring heated rooms for cold storage facilities, which can cost £5,000-£10,000 to install and £1,000-£2,000 annually to operate. These maintenance tasks require significant labour hours, with a professional battery topping service costing approximately £235 per battery per year. General forklift servicing, which may include battery checks, starts at £120, with an hourly labour rate of £58. Annual maintenance costs for lead-acid batteries are estimated to range from $200-$800. Handling lead-acid batteries poses inherent safety risks due to potential sulfuric acid leaks and the emission of flammable hydrogen gas during charging. This mandates well-ventilated charging areas, the use of Personal Protective Equipment (PPE), and the availability of spill kits and fire extinguishers.

Lithium-Ion: The Virtually Maintenance-Free Solution A standout advantage of lithium-ion batteries is their virtually maintenance-free nature. They are sealed units, eliminating the need for regular watering or electrolyte management, which also means no hazardous material spills. Lithium-ion batteries equalise automatically, negating the requirement for manual equalisation charges. Routine checks are minimal, primarily involving visual inspection for corrosion at terminals and monitoring battery health via the integrated Battery Management System (BMS). They perform well across a much wider temperature range, from -20°C to 45°C, experiencing less capacity loss in cold conditions (15-20% at 0°C). This significantly reduces or eliminates the need for heated charging rooms. The sophisticated BMS actively monitors internal conditions, optimises charging and discharge patterns, and provides early alerts for potential issues. The sealed design eliminates exposure to harmful acid and vapours, greatly enhancing workplace safety. The demanding maintenance regimen of lead-acid batteries requires significant labour, whether performed by in-house staff or outsourced, representing not only a direct cost but also a substantial opportunity cost. Lithium-ion technology virtually eliminates these labour-intensive tasks, freeing up valuable human capital. Furthermore, lead-acid batteries require dedicated, well-ventilated charging rooms, incurring substantial costs for allocating valuable warehouse space, installing specialised ventilation systems, and procuring necessary safety equipment. Lithium-ion batteries, being sealed and emission-free, eliminate the need for such extensive infrastructure and safety protocols, allowing for flexible charging anywhere on site. The elimination of dedicated charging rooms translates into the freeing up of valuable warehouse space, which can be repurposed for additional storage, new production lines, or other revenue-generating operations.

|

Feature |

Lead-Acid |

Lithium-Ion |

|

Watering Required |

Weekly (summer), Biweekly (winter) or every 5-10 cycles |

No |

|

Equalisation Required |

Monthly |

No |

|

Cleaning Frequency |

Monthly (terminals) |

Minimal (visual checks) |

|

Dedicated Charging Area Needed |

Yes (ventilated, safety equipment) |

No (flexible charging anywhere) |

|

Temperature Sensitivity |

High (20-25°C optimal, 30-40% loss at 0°C, prone to overheating) |

Low (-20 to 45°C optimal, 15-20% loss at 0°C) |

|

Estimated Annual Maintenance Labour Cost (£) |

£235 (topping service) to £800+ |

Minimal to zero |

|

Estimated Annual Maintenance Material Cost (£) |

£12-£300+ (deionised water, cleaning supplies) |

Minimal to zero |

|

Key Safety Considerations |

Acid spills, hydrogen gas explosion, PPE, ventilation, eye-wash stations |

Integrated BMS for safety, no emissions |

Battery Lifespan & Replacement: The Long-Term Investment

The longevity of a forklift battery and the associated costs of its eventual replacement are critical factors in determining the Total Cost of Ownership over an extended period.

Lifespan Comparison: Cycles and Years

-

Lead-Acid: Typically offer a lifespan of 1,000 to 1,500 charge cycles. This generally translates to approximately 3 to 5 years of service life under normal operating conditions. Improper maintenance can significantly shorten this lifespan.

-

Lithium-Ion: Provide a significantly longer operational lifespan, typically rated for 2,000 to 3,000 charge cycles. Some advanced Lithium Iron Phosphate (LFP) variants can even reach 3,500 to 5,000 cycles. In terms of years, this translates to an impressive 8 to 10 years, or even 10 to 12 years of service life.

Replacement Costs: Planning for the Future

-

Lead-Acid: The cost to replace a lead-acid forklift battery in the UK typically ranges from £1,000 to £3,000. Some sources indicate a slightly higher range of £3,613 to £4,976. A popular 48V – 37kWh lead-acid battery is priced around £5,682.

-

Lithium-Ion: Replacement costs for lithium-ion batteries are higher upfront, typically ranging from £5,000 to £10,000. Some comprehensive data suggests a range of £10,000 to £20,000. For instance, an 80V 775Ah lithium-ion battery can cost £11,827.

Despite the higher individual replacement cost, the need for fewer replacements over the operational lifetime is a major cost-saving factor for lithium-ion batteries. The compounding effect of multiple replacements for lead-acid dramatically inflates its TCO over a decade.

|

Feature |

Lead-Acid |

Lithium-Ion |

|

Typical Charge Cycles |

1,000 - 1,500 |

2,000 - 5,000 |

|

Estimated Lifespan (Years) |

3-5 years |

8-12 years |

|

Estimated Replacement Cost (New, UK £) |

£1,000 - £5,682 |

£5,000 - £20,000 |

|

Recycling Process/Cost |

Highly established, often FOC/scrap value (£0.20-£0.35/kg), hazardous waste documentation required |

Evolving infrastructure, current cost £3-£8/kg (export), must be discharged below 30% for disposal |

Downtime & Productivity: The True Operational Impact

Beyond direct financial outlays, the choice of forklift battery profoundly influences operational efficiency.

Lead-Acid: Productivity Bottlenecks and Space Demands The combination of long charging times (8-12 hours) and mandatory cooling periods (6-8 hours) means that a single lead-acid battery can realistically only support one shift per day. For multi-shift operations, businesses must invest in multiple batteries per forklift and dedicate significant time to battery changeovers. Swapping a heavy, 1.5-ton battery typically requires another forklift or an overhead crane, adding complexity and time to the process. These frequent battery changes lead to considerable downtime and a direct reduction in labour productivity. The cumulative effect of long charging times, mandatory cooling periods, and the necessity for time-consuming battery swaps in multi-shift operations significantly reduces the actual operational uptime of forklifts and consequently, operator productivity. Furthermore, the performance degradation of lead-acid batteries as they discharge compounds this issue, leading to slower operations and reduced productivity towards the end of a shift. Lead-acid batteries require dedicated, well-ventilated charging rooms due to the emission of hydrogen gas and the risk of acid spills, consuming valuable warehouse space.

Lithium-Ion: Uninterrupted Operations and Space Savings The rapid charging capabilities (1-3 hours for a full charge) and the ability to opportunity charge mean that a single lithium-ion battery can often support multi-shift or even 24/7 operations. This flexibility dramatically increases forklift uptime. The higher initial cost of lithium-ion can be rapidly offset by its ability to achieve greater output with fewer forklifts, fewer batteries, and more efficient utilisation of existing labour, leading to substantial overall savings. Lithium-ion technology eliminates the need for battery swaps and the associated dedicated charging rooms. This directly frees up valuable warehouse space, which can be repurposed for revenue-generating activities. Crucially, lithium-ion batteries provide consistent power output throughout their entire discharge cycle, ensuring sustained forklift performance and productivity, with no slowdowns or reduced lifting capacity experienced mid-shift. The reduced maintenance and reliable performance also minimise the risk of unexpected mid-shift breakdowns.

|

Feature |

Lead-Acid |

Lithium-Ion |

|

Full Charge Time (hours) |

8-12 |

1-3 |

|

Cooling Time (hours) |

6-8 |

0 |

|

Battery Swaps Required for Multi-Shift |

Yes (multiple batteries, dedicated labour, equipment) |

No (opportunity charging eliminates need) |

|

Impact on Operator Productivity |

Reduced uptime, time spent on battery management, performance degradation mid-shift |

Maximised uptime, consistent performance, minimal battery-related interruptions |

|

Space Requirements for Charging |

Dedicated, well-ventilated room required |

Flexible charging anywhere, no dedicated room needed |

|

Power Output Consistency |

Declining with discharge |

Consistent throughout discharge |

Operational Benefits Beyond Cost: The Added Value Proposition

Beyond quantifiable financial metrics, lithium-ion batteries offer a suite of operational advantages that contribute significantly to a business's overall value proposition, impacting safety, sustainability, and operational resilience.

Enhanced Safety and Workplace Environment Lead-acid batteries present inherent safety risks including potential acid spills, the emission of explosive hydrogen gas during charging, and the need for heavy, manual battery swaps. This necessitates the use of Personal Protective Equipment (PPE) and the availability of eye-wash stations. In contrast, lithium-ion batteries are sealed units, which completely eliminates the risk of acid spills and hazardous gas emissions. Their integrated Battery Management Systems (BMS) actively monitor and protect against overcharging, overheating, and deep discharge, significantly enhancing overall safety. Studies indicate a substantial reduction in battery-related injuries in facilities using lithium-ion (73% fewer). Furthermore, lithium-ion forklifts operate significantly quieter, reducing noise pollution, improving workplace communication, and decreasing operator stress and fatigue.

Environmental Advantages and Sustainability While lead-acid batteries boast a high recycling rate (99% in the US), their disposal still involves the handling of hazardous materials such as lead and sulfuric acid. Lithium-ion powered forklifts produce zero direct exhaust emissions during operation, contributing to cleaner indoor air quality. Their higher energy efficiency and longer lifespan result in a smaller overall carbon footprint. They also contain fewer toxic materials compared to lead-acid. Adopting lithium-ion technology directly aligns with green initiatives and corporate sustainability goals, enhancing a company's environmental credentials. For businesses with strong sustainability objectives, the environmental profile of lithium-ion adds significant non-monetary value.

Consistent Power Output and Temperature Resilience The performance of lead-acid batteries, including their voltage output and lifting capacity, visibly diminishes as their charge depletes. They are also highly sensitive to temperature fluctuations, losing significant capacity in cold environments (30-40% at 0°C) and prone to overheating during charging. In contrast, lithium-ion batteries maintain a consistent, high power output throughout their entire discharge cycle. This ensures forklifts operate at optimal levels from the beginning to the end of a shift, without performance drops. They also boast superior temperature resilience, functioning efficiently in a wider range of temperatures (-20°C to 45°C) with minimal capacity loss in cold conditions (15-20% at 0°C). This makes them an ideal choice for challenging environments such as cold storage facilities.

Conclusion

The decision between lead-acid and lithium-ion forklifts for UK businesses is a complex one, extending far beyond the initial purchase price. While lead-acid batteries offer a lower upfront investment, their long-term Total Cost of Ownership (TCO) is significantly impacted by higher energy consumption due to lower efficiency, extensive and costly maintenance requirements, shorter lifespans necessitating more frequent replacements, and substantial productivity losses due to prolonged charging times and battery swaps. These factors create a "hidden energy tax" and a "productivity tax" that accumulate over time, often making the seemingly cheaper lead-acid option more expensive in the long run.

Conversely, lithium-ion batteries, despite their higher initial outlay, emerge as a compelling long-term investment. Their superior energy efficiency translates into tangible electricity bill savings. The virtually maintenance-free nature and ability to "opportunity charge" dramatically reduce labour costs, eliminate the need for dedicated charging infrastructure, and free up valuable warehouse space for more productive uses. The significantly longer lifespan of lithium-ion batteries means fewer costly replacements over the operational life of the forklift, effectively reducing the annualised capital expenditure on batteries. Beyond direct costs, lithium-ion technology offers substantial non-monetary benefits, including enhanced workplace safety, a reduced environmental footprint, and consistent power output that maintains peak forklift performance throughout shifts, even in challenging temperatures.

For businesses operating in high-volume, multi-shift environments, the operational flexibility and continuous uptime offered by lithium-ion batteries can lead to substantial gains in throughput and overall efficiency, quickly offsetting the initial investment. For those with strong sustainability objectives, the environmental advantages of lithium-ion further reinforce its value proposition.

Ultimately, an informed decision requires a comprehensive TCO analysis tailored to specific operational needs, usage patterns, and long-term strategic goals. While lead-acid continues to serve as a reliable, lower-entry option for lighter-duty or single-shift operations with strict upfront budget constraints, the evidence strongly suggests that lithium-ion technology offers a more cost-effective, productive, and sustainable solution for the majority of modern UK material handling operations over time.